Very nice

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Kelly W's Axe & Knife Adventures

- Thread starter Kelly W

- Start date

A good axe head on a truly nice handle.Nifty little work in progress. 1 3/4lb Snow & Nealley Bangor. Should finish up at about 17 inches.

View attachment 2109339

View attachment 2109340

It's so cute.Commissioned Norlund saddle axe project arrived today. Crazy the prices on these things today. This on will get the full treatment.

View attachment 2114934

View attachment 2114935

View attachment 2114936

Can't wait to so what you do with it.

- Joined

- Mar 1, 2017

- Messages

- 8,589

- Likes

- 69,342

- Joined

- Jun 4, 2021

- Messages

- 3,761

- Likes

- 32,876

That’s going to be a nice upgrade.Haven’t been any axe/knife work the last couple weeks. Been doing a bunch of outdoor/lawn chores and getting the garden put in.

Do have a bit of exciting shop upgrade news!

Some a/c for the summer!

View attachment 2124054

COOL!Haven’t been any axe/knife work the last couple weeks. Been doing a bunch of outdoor/lawn chores and getting the garden put in.

Do have a bit of exciting shop upgrade news!

Some a/c for the summer!

View attachment 2124054

Mighty fine workRecently completed Snow&Nealley Hudson and Norlund saddle axe

View attachment 2132227

View attachment 2132228

View attachment 2132229

View attachment 2132230

View attachment 2132231

View attachment 2132232

View attachment 2132233

Looking good brother, always enjoy seeing what you're coming up with.

- Joined

- Mar 1, 2017

- Messages

- 8,589

- Likes

- 69,342

Thank you! ...slow and steady :4:Looking good brother, always enjoy seeing what you're coming up with.

- Joined

- Jun 4, 2021

- Messages

- 3,761

- Likes

- 32,876

They turned out great!! Glad to see you getting back after it!Before and after etch. The two blades were media blasted, etched in ferric and tumbled.

View attachment 2159204

- Joined

- Mar 1, 2017

- Messages

- 8,589

- Likes

- 69,342

Last edited:

- Joined

- Jun 4, 2021

- Messages

- 3,761

- Likes

- 32,876

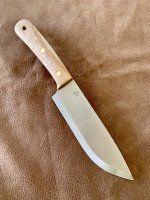

Two beauty’s! The knife and scales. Beautiful work!!Need to give our friend @T. Pollock a big shout out for this beautiful birch!

View attachment 2164616

View attachment 2164617

- Joined

- Nov 5, 2017

- Messages

- 4,586

- Likes

- 20,260

I'd say you both deserve a shoutout! Well done.Need to give our friend @T. Pollock a big shout out for this beautiful birch!

View attachment 2164616

View attachment 2164617

Need to give our friend @T. Pollock a big shout out for this beautiful birch!

View attachment 2164616

View attachment 2164617

That looks awesome my friend! Thank you for tagging me, I love seeing wood I couldn't use being put to good use.

The camp knife looks awesome as well!

Last edited:

- Joined

- Mar 1, 2017

- Messages

- 8,589

- Likes

- 69,342

So here is a little project my buddy Paul aka @BoBo56 sent to me. It's a 3v Architect. Thought Id share a few photos of my process. I use a jig as I'm a shaky old man. Ya need to mount the blade in a fashion so as you can duplicate the mounting for the other side. Then get the angle right against the platen. You also need to mark and measure the blade height on the jig. This is another important detail when you flip it to grind the other side. I used two locations on this one.

Then you go for it! I wet grind with a water mister so as not to overheat the blade as I grind. I was happy how this worked out. Should be useable now!

This one was way thick behind the edge. I took it from .035 to .010.

Then you go for it! I wet grind with a water mister so as not to overheat the blade as I grind. I was happy how this worked out. Should be useable now!

This one was way thick behind the edge. I took it from .035 to .010.

- Joined

- Jun 4, 2021

- Messages

- 3,761

- Likes

- 32,876

Beautiful work Tim!! Now I’ll actually be able to use it as a knife! Pretty impressive process as well! Thank you very much!So here is a little project my buddy Paul aka @BoBo56 sent to me. It's a 3v Architect. Thought Id share a few photos of my process. I use a jig as I'm a shaky old man. Ya need to mount the blade in a fashion so as you can duplicate the mounting for the other side. Then get the angle right against the platen. You also need to mark and measure the blade height on the jig. This is another important detail when you flip it to grind the other side. I used two locations on this one.

Then you go for it! I wet grind with a water mister so as not to overheat the blade as I grind. I was happy how this worked out. Should be useable now!

This one was way thick behind the edge. I took it from .035 to .010.

View attachment 2166508

View attachment 2166509

View attachment 2166511

View attachment 2166510

View attachment 2166512

- Joined

- Mar 1, 2017

- Messages

- 8,589

- Likes

- 69,342

Not so much@Kelly W regrind services!!!

Thank you! :dblthumb:Beautiful work Tim!! Now I’ll actually be able to use it as a knife! Pretty impressive process as well! Thank you very much!